-

Highlight

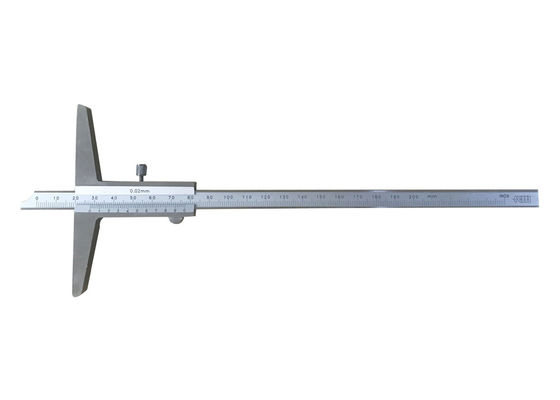

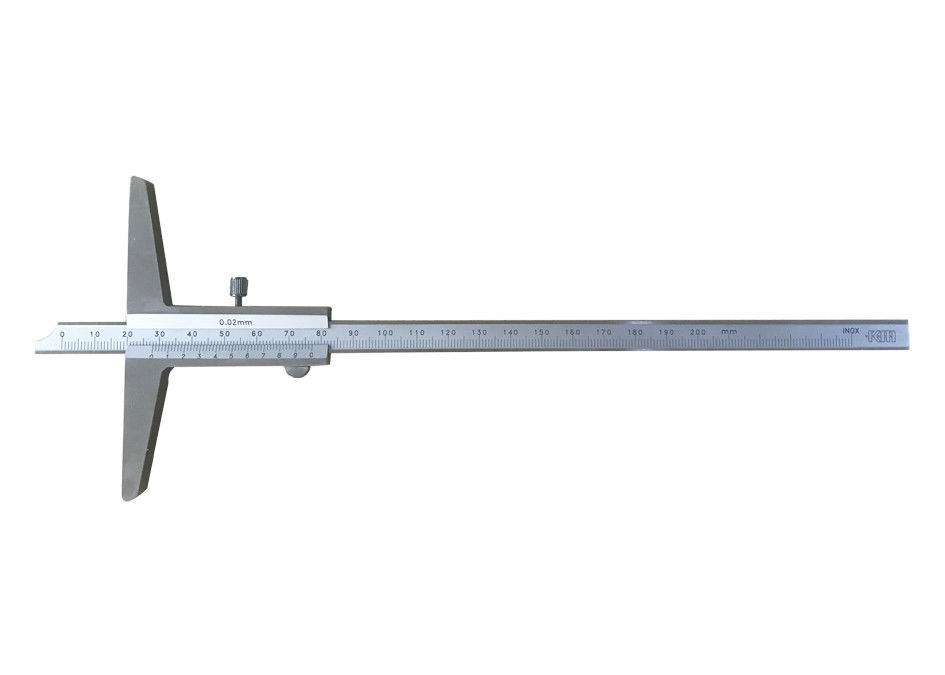

Stainless Steel Depth Caliper

,Hardened Depth Caliper

-

WarrantyOne Year

-

TypeDepth Vernier Caliper

-

MaterialStainless Steel

-

Measurement ObjectDepth Measurement

-

MeasurementMetric

-

Range0-200mm

-

Graduation0.02mm

-

Precision±0.03mm

-

FormOpen And Close Type

-

PackageABS Box

-

Place of OriginShaanxi, China

-

Brand NameKM

-

CertificationISO DIN GB RoHS

-

Model NumberKM-VDC200

-

Packaging DetailsABS Box 25*15*4cm/Piece 0.90kg/Piece

-

Delivery TimeWithin 15days

-

Payment TermsT/T,L/C,D/P,D/A,Western Union,PayPal,MoneyGram

-

Supply Ability50000pieces/Month

0-200mm Stainless Steel Hardened Vernier Depth Caliper

0-200mm Stainless Steel Hardened Vernier Depth Caliper

Quick Overview

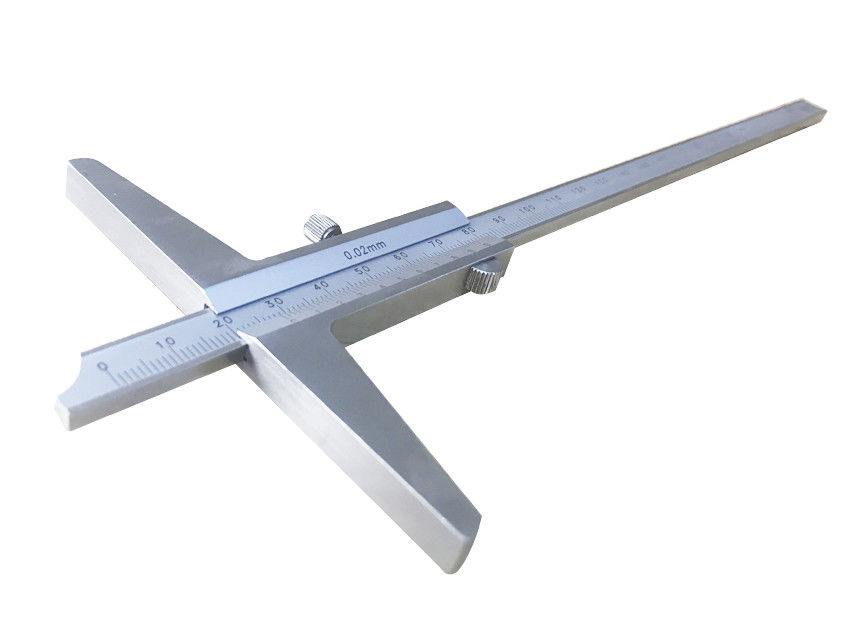

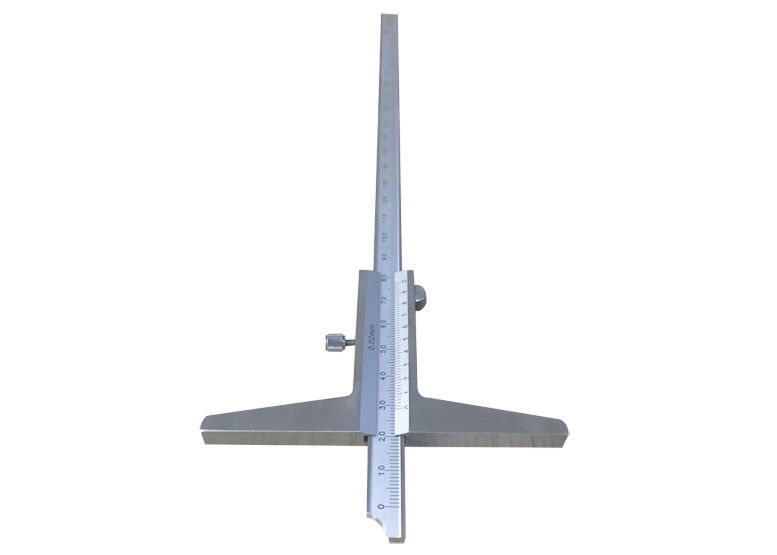

- Stainless-steel hardened base and measuring face for precise depth dimension measurement

- Laser-etched scale for clear, easy reading

- Supplied in protective fitted case

Product Description

The KM-VDC series represents our standard vernier depth caliper line, engineered for accurate depth and step measurements. Constructed from durable stainless steel, these calipers are available in measuring ranges from 0-150mm up to 0-600mm to accommodate diverse measurement requirements.

Our depth calipers deliver high measurement accuracy, making them suitable for precision machining and inspection applications. The well-designed structure ensures ease of operation, allowing users to quickly achieve accurate measurements. Built for durability and stability, these vernier depth calipers maintain reliable performance across various working environments.

Technical Specifications

| Order No. | Measuring Range | Graduation | Accuracy |

|---|---|---|---|

| KM-VDC150 | 0-150mm | 0.02mm | ±0.03mm |

| KM-VDC200 | 0-200mm | 0.02mm | ±0.03mm |

| KM-VDC300 | 0-300mm | 0.02mm | ±0.04mm |

| KM-VDC500 | 0-500mm | 0.02mm | ±0.05mm |

Operation Guidelines

- Clean measuring surfaces before use to prevent dust and impurities from damaging the tool

- Ensure the measuring base and caliper end face are perpendicular to the measured surface and fit tightly without skewing

- Measure machine parts only when completely stable

- When measuring groove depth or curved surfaces, position the measuring base on the curve's highest point for accurate results

- Avoid applying excessive pressure during measurement to prevent caliper bending, base wear, and inaccurate readings

- Increase measurement accuracy by taking multiple readings in different directions and calculating the average

Industrial Applications

- Machining: Essential for turning, drilling, and milling operations to measure workpiece depth and length with precision

- Part Manufacturing: Verifies specific dimensions and spacing to ensure manufacturing accuracy

- Quality Control: Critical for industrial inspection processes, checking product dimensions, depth, and spacing against quality standards

Frequently Asked Questions

- Company Background: Deko Corporation specializes in developing, manufacturing, and marketing KM brand precision measuring tools in China mainland

- Product Range: Comprehensive selection including dial indicators, micrometers, calipers, bore gauges, height gauges, thickness gauges, depth gauges, bevel protractors, gauge blocks, and levels

- Trade Terms: Support for FOB, CFR, CIF, and EXW

- Payment Methods: Accept T/T, L/C, D/A, D/P, PayPal, and Western Union

- Customization: OEM services available

- After-Sales Service: One-year warranty with replacement of defective parts or products; strict calibration and inspection processes ensure product quality