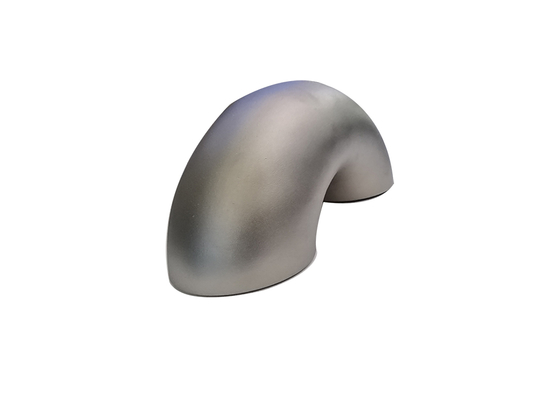

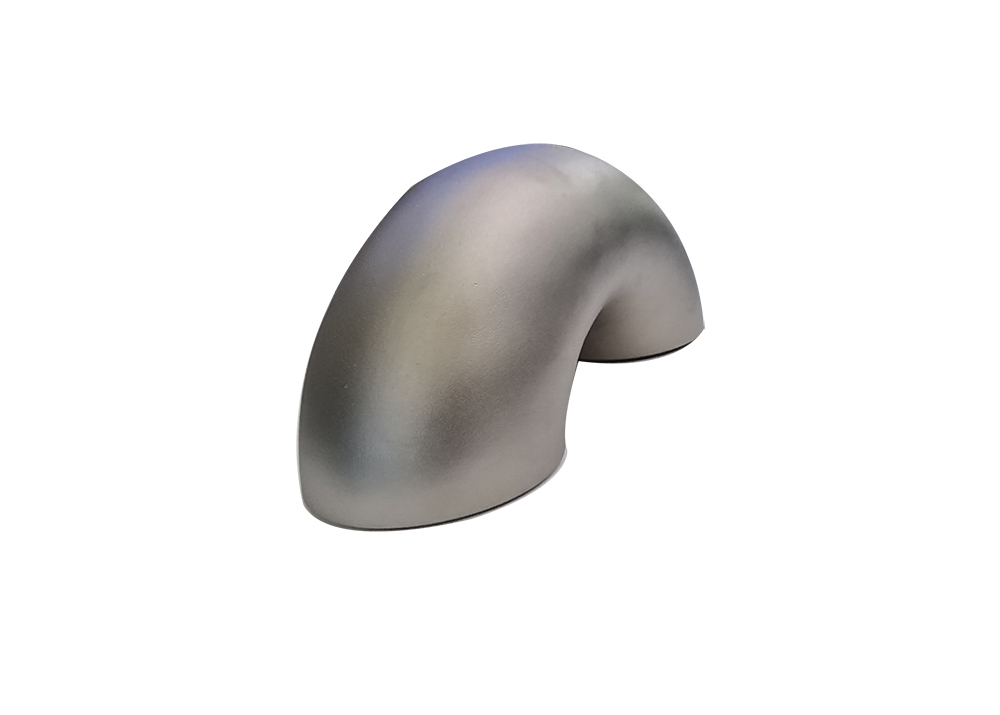

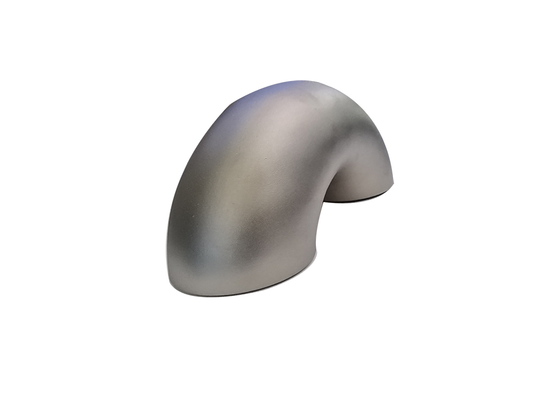

ASME B16.9 180 Degree titanium Seamless Butt Weld Elbow

-

Highlight

Seamless 180 Degree Elbow

,Seamless Butt Weld Elbow

,ASME B16.9 180 Degree Elbow

-

Material DesignationTA1/TA2/TA9/TA10/GR1/GR2/GR7/GR12/N5/N6 Etc

-

SizeDN15-DN600

-

OEM&ODMAvailable

-

Surface FinishShot Blasting, Sand Blasting

-

TechnicsWelding, Seamless

-

Place of OriginShaanxi, China

-

Brand NameVOTECH

-

CertificationASTM B16.9,GB/T27684-2011

-

Model NumberCustomized

-

Packaging DetailsExport Standard Wooden Case, or Can Be Customized

-

Delivery Time7-15 Days

-

Payment TermsL/C,D/A,D/P,T/T,Western Union,MoneyGram

-

Supply Ability100ton/Month

ASME B16.9 180 Degree titanium Seamless Butt Weld Elbow

ASME B16.9 180 Degree Titanium Seamless Butt Weld Elbow

Titanium long radius 180 degree elbows are essential components in high-demand industries including chemical processing, petroleum, and power generation. Their exceptional corrosion resistance withstands harsh acid and alkali media in chemical equipment, ensuring long-term pipeline stability. In marine applications, these elbows resist seawater corrosion, significantly extending equipment service life.

These titanium pipe fittings efficiently change fluid direction in pipeline systems while offering superior corrosion and high-temperature resistance. Available in sizes from DN15 to DN600, we also provide custom solutions to meet specific requirements. Our products strictly adhere to ASME B16.9 and GB/T27684-2011 international standards.

Product Specifications

| Standard | ASME B16.9, GB/T27684-2011 |

| Material Designation | TA1/TA2/TA9/TA10/GR1/GR2/GR7/GR12/N5/N6 etc |

| Size | DN15-DN600 |

| OEM/ODM | Available |

| Surface Finish | Shot blasting, Sand blasting |

| Technics | Welding, Seamless |

| Type | Titanium 180° Elbow |

| Packaging | Export Standard Wooden case, or can be customized |

| Application | Chemical, petrochemical and general industries: electrolytic cells, reactors, distillation towers, concentrators, separators, heat exchangers, pipelines, electrodes, etc. Marine engineering: seawater desalination pipelines, offshore oil drilling pumps, valves, and pipe fittings |

Dimensional Specifications (mm)

|

Nominal Diameter |

Outside diameter at bevel |

center to center |

Back to end |

|||||

|

Major radius |

Short radius |

|||||||

|

ⅠSeries |

ⅡSeries |

Major radius |

Short radius |

ⅠSeries |

ⅡSeries |

ⅠSeries |

ⅡSeries |

|

|

15 |

21.3 |

18 |

76 |

— |

48 |

47 |

— |

— |

|

20 |

26.7 |

25 |

76 |

— |

51 |

51 |

— |

— |

|

25 |

33.4 |

32 |

76 |

51 |

56 |

54 |

41 |

41 |

|

32 |

42.2 |

38 |

95 |

64 |

70 |

67 |

52 |

51 |

|

40 |

48.3 |

45 |

114 |

76 |

83 |

80 |

62 |

61 |

|

50 |

60.3 |

57 |

152 |

102 |

106 |

105 |

81 |

79 |

|

65 |

73.0 |

76 |

190 |

127 |

132 |

133 |

100 |

102 |

|

80 |

88.9 |

89 |

229 |

152 |

159 |

159 |

121 |

121 |

|

90 |

101.6 |

— |

267 |

178 |

184 |

— |

140 |

— |

|

100 |

114.3 |

108 |

305 |

203 |

210 |

206 |

159 |

156 |

|

125 |

141.3 |

133 |

381 |

254 |

262 |

257 |

197 |

194 |

|

150 |

168.3 |

159 |

457 |

305 |

313 |

308 |

237 |

232 |

|

200 |

219.1 |

219 |

610 |

406 |

414 |

414 |

313 |

313 |

|

250 |

273.0 |

273 |

762 |

508 |

518 |

518 |

391 |

391 |

|

300 |

323.8 |

325 |

914 |

610 |

619 |

620 |

467 |

467 |

|

350 |

355.6 |

377 |

1 067 |

711 |

711 |

722 |

533 |

544 |

|

400 |

406.4 |

426 |

1 219 |

813 |

813 |

823 |

610 |

619 |

|

450 |

457 |

480 |

1 372 |

914 |

914 |

925 |

686 |

697 |

|

500 |

508 |

530 |

1 524 |

1 016 |

1 016 |

1 026 |

762 |

773 |

|

550 |

559 |

— |

1 676 |

1 118 |

1 118 |

— |

838 |

— |

|

600 |

610 |

630 |

1 829 |

1 219 |

1 219 |

1 229 |

914 |

925 |

Frequently Asked Questions

What are the outstanding performances of titanium pipe fittings in terms of corrosion resistance?

Titanium pipe fittings exhibit exceptional resistance to corrosive media including seawater and chloride ions, significantly outperforming stainless steel and carbon steel. This makes them ideal for demanding environments in marine and chemical industries.

Do titanium 180° elbows need additional anti-rust measures?

No additional protection is required. Titanium 180° elbows maintain integrity without coatings or cathodic protection, eliminating rust risk and reducing maintenance needs.

Where does the lightweight advantage of titanium 180 degree elbows lie?

With strength comparable to steel but only 60% of its density, titanium elbows significantly reduce equipment weight in aerospace and shipbuilding applications while maintaining structural integrity.

How is the high-temperature resistance of titanium long radius returns?

Titanium alloys (TA2, TA9) maintain stable mechanical properties at 300-500℃, with some grades capable of withstanding even higher temperatures for short durations.

Why are titanium pipe fittings still economical despite their high initial cost?

While initial costs are higher, titanium's extended service life and minimal maintenance requirements result in superior long-term cost efficiency compared to alternative materials.

Are titanium pipe fittings suitable for the pharmaceutical and food industries?

Absolutely. Titanium's non-toxic, biocompatible nature and high material purity meet stringent hygiene requirements for pharmaceutical and food processing applications.

Our Advantages

Superior Quality: Rigorous quality control adhering to ASME, JIS, DIN, GB, GOST standards ensures all titanium products meet industry requirements.

Modern Production Facilities: Advanced manufacturing capabilities enable bulk orders and customized solutions.

Logistics and Packaging: Secure wooden packaging prevents transit damage, ensuring product safety.

Experienced Team: Decades of titanium manufacturing expertise guarantees high-quality products.

Comprehensive Service: Custom solutions, fast lead times, and dedicated support throughout procurement.

Customer-Centric Services: Flexible payment options, technical support, and seamless purchasing experience.