Industrial 30Pcs Surface Roughness Comparator Kit for Blasting Painting Welding

-

Highlight

industrial surface roughness comparator kit

,30pcs blasting painting gauge blocks

,welding surface roughness comparator

-

WarrantyOne Year

-

Measurement ObjectSurface Roughness

-

Range0.05-12.5um

-

ShapeRectangular

-

For Surface TypeGround, Lapped, Milled, Reamed, Turned

-

No. Of Swatches30

-

PackagePVC Wallet

-

Place of OriginShaanxi, China

-

Brand NameKM

-

CertificationISO DIN GB RoHS

-

Model NumberKM-SRC-30

-

Packaging DetailsPVC Wallet 16*8*1.2cm/Piece 0.35kg/Piece

-

Delivery TimeWithin 15days

-

Payment TermsT/T,L/C,D/P,D/A,Western Union,PayPal,MoneyGram

-

Supply Ability50000pieces/Month

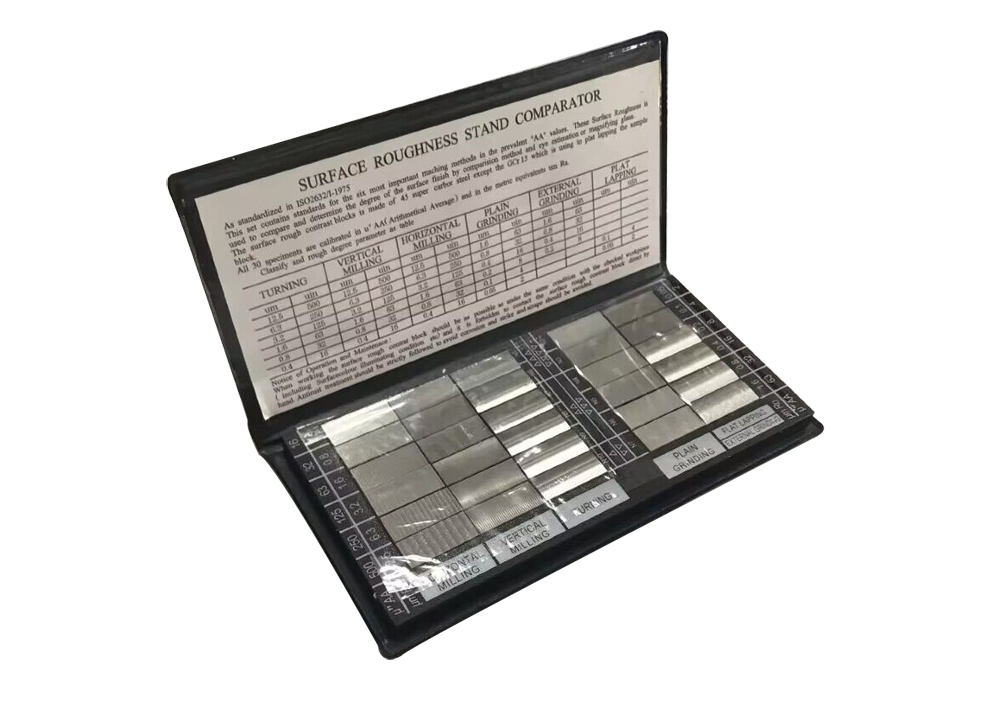

Industrial 30Pcs Surface Roughness Comparator Kit for Blasting Painting Welding

Surface roughness comparator is used to check the smoothness of mechanical workpieces by comparison, while the visual inspection

or microscope is used to compare and test the degree of exterior roughness.

Surface comparator gauge set contains standards for the six most important processing methods among the popular "AA" values.

Sample exterior roughness comparator 30 pieces of composite bag fixing gauges.

Each type of exterior finish is a true and consistent reproduction, with a true idea of the feel, appearance and texture of machined parts

Compare conveniently and quickly; Comply with S.A.E and specifications.

Overall wallet size L x W x H (mm): 16 x 8 x1cm Unit weight: 0.30kgs.

30Pcs surface roughness stand comparator is a precision-engineered tool for visual and tactile surface profile evaluation in industrial

applications and covers all common roughness ranges from 12.5μm to 100μm. It also provides ISO compliant reference standards

for accurate comparison of surface roughness after blasting, grinding, or machining operations.

- Contains 30 comparison specimens covering six common machining methods.

- True and consistent reproduction of surface finishes with realistic feel and appearance.

- Covers roughness ranges from 12.5μm to 100μm.

- Complies with S.A.E specifications.

- Compact wallet size: 16 x 8 x 1 cm (L x W x H).

- Lightweight at 0.30 kgs.

- Includes PVC wallet packing for protection and organization.

| Order No. | No. of Swatches | Surface Finish Range | Length | Width | Material |

|---|---|---|---|---|---|

| KM-SRC-30 | 30 | 0.05-12.5μm | 22mm | 7mm | Carbon Steel |

| Turning | Vertical Milling | Horizontal Milling | Plain Grinding | External Grinding | Plat Lapping |

|---|---|---|---|---|---|

| 12.5μm (500uin) | 12.5μm (500uin) | 12.5μm (500uin) | 1.6μm (63uin) | 1.6μm (63uin) | |

| 6.3μm (250uin) | 6.3μm (250uin) | 6.3μm (250uin) | 0.8μm (32uin) | 0.8μm (32uin) | |

| 3.2μm (125uin) | 3.2μm (125uin) | 3.2μm (125uin) | 0.4μm (16uin) | 0.4μm (16uin) | |

| 1.6μm (63uin) | 1.6μm (63uin) | 1.6μm (63uin) | 0.2μm (8uin) | 0.2μm (8uin) | |

| 0.8μm (32uin) | 0.8μm (32uin) | 0.8μm (32uin) | 0.1μm (4uin) | 0.1μm (4uin) | |

| 0.4μm (16uin) | 0.4μm (16uin) | 0.4μm (16uin) | 0.05μm (2uin) | 0.05μm (2uin) |

- Clean the test surface using a cloth before use.

- Always handle specimens by edges to prevent surface contamination.

- Never slide specimens across test surfaces - use vertical placement only.

- Immediately return each specimen to its designated case compartment after use.

- Store in a controlled environment after use.

- Paint adhesion testing - Measures anchor pattern depth (12.5-100μm range) prior to coating application.

- Sheet metal forming - Checks tooling wear-induced surface variations.

- Pipeline corrosion repair - Assesses blast profile before wrap/coating.

- Bridge rehabilitation - Confirms concrete steel substrate preparation.