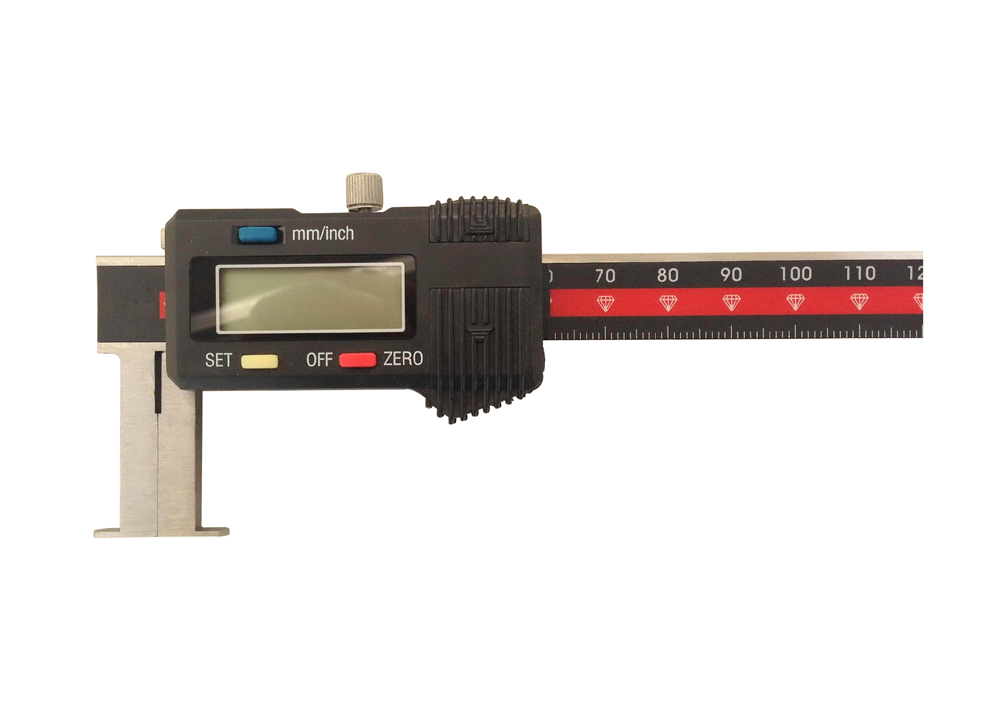

Digital Inside Groove Caliper with Flat Points for Internal Groove Measurement

-

Highlight

Internal Groove Caliper with Flat Points

,Digital Internal Groove Caliper

,Internal Groove Caliper

-

WarrantyOne Year

-

MeasurementMetric/Inch

-

Product TypeInternal Groove & Bore Measurement

-

Jaw TypeKnife-Edge Jaws

-

Anvil DesignCentral Groove

-

Slider MechanismSmooth Gliding Action

-

MaterialStainless Steel

-

Display TypeDigital LCD Display

-

Included AccessoriesUser Manual

-

PackageABS Case

-

Place of OriginShaanxi, China

-

Brand NameKM

-

CertificationISO DIN GB RoHS

-

Model NumberKM-DIGF-150

-

Packaging DetailsAluminum Case 35*17*5cm/Piece 0.66kg/Piece

-

Delivery TimeWithin 15days

-

Payment TermsT/T,L/C,D/P,D/A,Western Union,PayPal,MoneyGram

-

Supply Ability50000pieces/Month

Digital Inside Groove Caliper with Flat Points for Internal Groove Measurement

Digital Inside Groove Caliper with Flat Points for Internal Groove Measurement

Product Description

Digital inside groove caliper features specialty jaws that project straight and parallel to each other for measuring narrow inside grooves.

The hardened stainless-steel construction provides excellent durability

Large LCD display that displays the measurement results for easy reading and provides instant metric/imperial conversion

and zero-setting at any position. Digital inside groove caliper with the flat contact points, which enable precise measurement of groove

bottom surfaces.

Key Features

- Resolution: 0.01mm (Metric); 0.0005" (Inch).

- Flat anvil design for measuring narrow grooves in holes.

- Clear LCD display for easy reading.

- Inch/metric conversion capability.

- Power on/off function.

- Zero setting at any position.

- Includes protective case.

Technical Specifications

| Order No. | Range | Resolution | Accuracy |

|---|---|---|---|

| KM-DIGF-150 | 22-150mm/0.86-6" | 0.01mm/0.0005" | ±0.04mm |

| KM-DIGF-150-1 | 35-150mm/1.4-6" | 0.01mm/0.0005" | ±0.05mm |

| KM-DIGF-200 | 25-200mm/1-8" | 0.01mm/0.0005" | ±0.04mm |

| KM-DIGF-200-1 | 40-200mm/1.6-8" | 0.01mm/0.0005" | ±0.05mm |

| KM-DIGF-300 | 30-300mm/1.2-12" | 0.01mm/0.0005" | ±0.05mm |

| KM-DIGF-300-1 | 50-300mm/2-12" | 0.01mm/0.0005" | ±0.06mm |

| KM-DIGF-500 | 40-500mm/1.6-20" | 0.01mm/0.0005" | ±0.06mm |

| KM-DIGF-500-1 | 60-500mm/2.4-20" | 0.01mm/0.0005" | ±0.07mm |

| KM-DIGF-500-2 | 80-500mm/3.2-20" | 0.01mm/0.0005" | ±0.07mm |

Industrial Applications

This digital inside groove micrometer is designed for internal groove measurement applications across multiple industries.

Its unique flat-point design enables accurate measurement of groove widths, depths, and internal diameters in various machining components,

making it essential for quality control and production verification.

- Machining & Manufacturing: Precise measurement of internal grooves in turned parts, bored components, and machined workpieces.

- Automotive Engineering: Inspection of piston ring grooves, valve guide grooves, and transmission component grooves.

- Bearing Production: Verification of bearing raceway grooves and retaining ring grooves.

Usage Precautions

- Ensure the measured groove and caliper jaws are clean before use.

- Do not force the caliper into grooves smaller than its minimum measuring range.

- Clean measuring surfaces regularly with a soft, lint-free cloth.

- Avoid using solvents or abrasive cleaners that may damage the LCD or scale.

Frequently Asked Questions

Who are we?

Deko Corporation is primarily dedicated to the development, manufacture and marketing of KM brand precision measuring tools in China mainland.

What products do we carry?

Dial indicators, micrometers, calipers, bore gauges, height gauges, dial thickness gauges, depth gauges, bevel protractors, gauge blocks, levels, etc.

What are the terms of trade?

We support FOB, CFR, CIF, EXW.

What are the forms of payment?

We accept T/T, L/C, D/A, D/P, PayPal, Western Union.

Do we accept customization?

Yes, OEM is available.

How about after-sales service?

One year warranty for all products. If you find any defective accessories when receiving goods, we will ship replacement parts or products.

As an experienced manufacturer, we have strict calibration and inspection processes to ensure product quality.