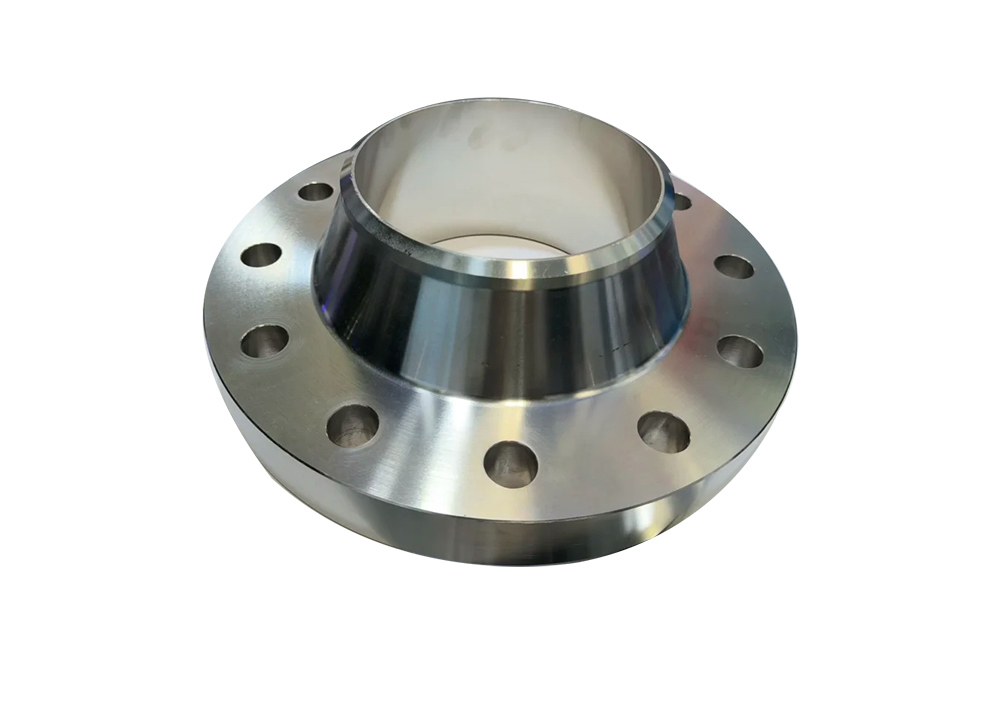

Custom High Precision Metal Titanium Weld Neck Flange

-

Highlight

Metal Titanium Weld Neck Flange

,Custom High Precision Titanium Flange

,High Precision Metal Titanium Flange

-

MaterialTA1,TA2,TA9,TA10,GR1,GR2,GR7,GR12,GR16,N5,N6,N7 Etc

-

SizeNPS 1/2-NPS 24

-

OEM/ODMAvailable

-

PressureClass150,Class300,Class600,Class900,Class1500,Class2500

-

TechnicsTechnics

-

Sealing SurfaceRF,MFM,TG,FF,RJ

-

Place of OriginShaanxi,China

-

Brand NameVOTECH

-

CertificationASME,ANSI

-

Model NumberNPS 1/2-NPS 24

-

Packaging DetailsExport Standard Wooden Case, or Can Be Customized

-

Delivery Time7-15 Days

-

Payment TermsL/C,D/A,D/P,T/T,Western Union,MoneyGram

-

Supply Ability100ton/Month

Custom High Precision Metal Titanium Weld Neck Flange

Titanium weld neck flanges excel in systems used in chemical, offshore, aerospace, and high-purity media transport applications. Precision-forged from high-quality titanium, their exceptional corrosion resistance ensures long-term structural integrity and sealing reliability in harsh environments, significantly reducing maintenance costs and extending equipment life.

Weld neck titanium flanges are pipe fittings with a round tube transition structure. They are welded to the pipe and are primarily used in high-pressure, high-temperature, or media-sensitive piping systems. The flared transition neck structure distances the weld from the sealing surface, reducing weld distortion and improving sealing performance. This design significantly enhances system sealing and long-term stability under demanding conditions.

Our titanium flanges are available in all standard sizes to meet your needs. With robust customization capabilities, we can produce flanges to meet specific pressure ratings, connection standards, or special dimensions. Whether standard or custom, we provide high-quality titanium flange solutions tailored to your precise requirements.

| Standard | ASME, ANSI |

|---|---|

| Material Designation | TA1, TA2, TA9, TA10, GR1, GR2, GR7, GR12, GR16, N5, N6, N7 etc |

| Size | NPS 1/2 - NPS 24 |

| OEM & ODM | Available |

| Pressure | Class150, Class300, Class600, Class900, Class1500, Class2500 |

| Technics | Forged |

| Sealing surface | RF, MFM, TG, FF, RJ |

| Type | Weld Neck Flange |

| Packaging | Export standard wooden case, or can be customized |

| Application | Petroleum, chemical, shipbuilding, pharmaceutical, metallurgy, machinery, stamping elbow, food and other industries |

|

Nominal Dimension |

Outside diameter |

Connection size |

Flange thickness |

Flange neck big end |

Flange inner diameter |

Flange height |

|||||

|

DN |

NPS |

Flange outer diameter |

Diameter of center circle of bolt hole |

Bolt hole |

Bolt |

Number of bolt holes |

|||||

|

15 |

1/2 |

21.3 |

90 |

60.3 |

16 |

M14 |

4 |

9.6 |

30 |

15.5 |

46 |

|

20 |

3/4 |

26.9 |

100 |

69.9 |

16 |

M14 |

4 |

11.2 |

38 |

21 |

51 |

|

25 |

1 |

33.7 |

110 |

79.4 |

16 |

M14 |

4 |

12.7 |

49 |

27 |

54 |

|

32 |

1-1/4 |

42.4 |

115 |

88.9 |

16 |

M14 |

4 |

14.3 |

59 |

35 |

56 |

|

40 |

1-1/2 |

48.3 |

125 |

98.4 |

16 |

M14 |

4 |

15.9 |

65 |

41 |

60 |

|

50 |

2 |

60.3 |

150 |

120.7 |

18 |

M16 |

4 |

17.5 |

78 |

52 |

62 |

|

65 |

2-1/2 |

76.1 |

180 |

139.7 |

18 |

M16 |

4 |

20.7 |

90 |

66 |

68 |

|

80 |

3 |

88.9 |

190 |

152.4 |

18 |

M16 |

4 |

22.3 |

108 |

77.5 |

68 |

|

100 |

4 |

114.3 |

230 |

190.5 |

18 |

M16 |

8 |

22.3 |

135 |

101.5 |

75 |

|

125 |

5 |

139.7 |

255 |

215.9 |

22 |

M20 |

8 |

22.3 |

164 |

127 |

87 |

|

150 |

6 |

168.3 |

280 |

241.3 |

22 |

M20 |

8 |

23.9 |

192 |

154 |

87 |

|

200 |

8 |

219.1 |

345 |

298.5 |

22 |

M20 |

8 |

27.0 |

246 |

203 |

100 |

|

250 |

10 |

273 |

405 |

362.0 |

26 |

M24 |

12 |

28.6 |

305 |

255 |

100 |

|

300 |

12 |

323.9 |

485 |

431.8 |

26 |

M24 |

12 |

30.2 |

365 |

303.5 |

113 |

|

350 |

14 |

355.6 |

535 |

476.3 |

30 |

M27 |

12 |

33.4 |

400 |

— |

125 |

|

400 |

16 |

406.4 |

595 |

539.8 |

30 |

M27 |

16 |

35.0 |

457 |

— |

125 |

|

450 |

18 |

457 |

635 |

577.9 |

33 |

M30 |

16 |

38.1 |

505 |

— |

138 |

|

500 |

20 |

508 |

700 |

635.0 |

33 |

M30 |

20 |

41.3 |

559 |

— |

143 |

|

600 |

24 |

610 |

815 |

749.3 |

36 |

M33 |

20 |

46.1 |

663 |

— |

151 |

Titanium weld neck flanges have extremely strong resistance to corrosive media such as seawater and chloride ions. Their corrosion resistance far exceeds that of stainless steel and carbon steel, making them especially suitable for harsh environments such as marine and chemical industries.

No need. Titanium weld neck flanges can be used for a long time without coating or cathodic protection, avoiding the risk of rust and significantly reducing maintenance requirements.

- Strict Quality: Rigorous quality control measures with ASME, JIS, DIN, GB, GOST standards

- Modern Production Facilities: Advanced factory with multiple titanium metal production lines

- Logistics and Packaging: Carefully packed in wood cabins or trays for maximum protection

- Experienced Team: Years of professional knowledge in titanium metal manufacturing

- Comprehensive Service: Customized solutions, fast lead times, and dedicated support

- Customer-Centric Services: Flexible payment options and comprehensive technical support