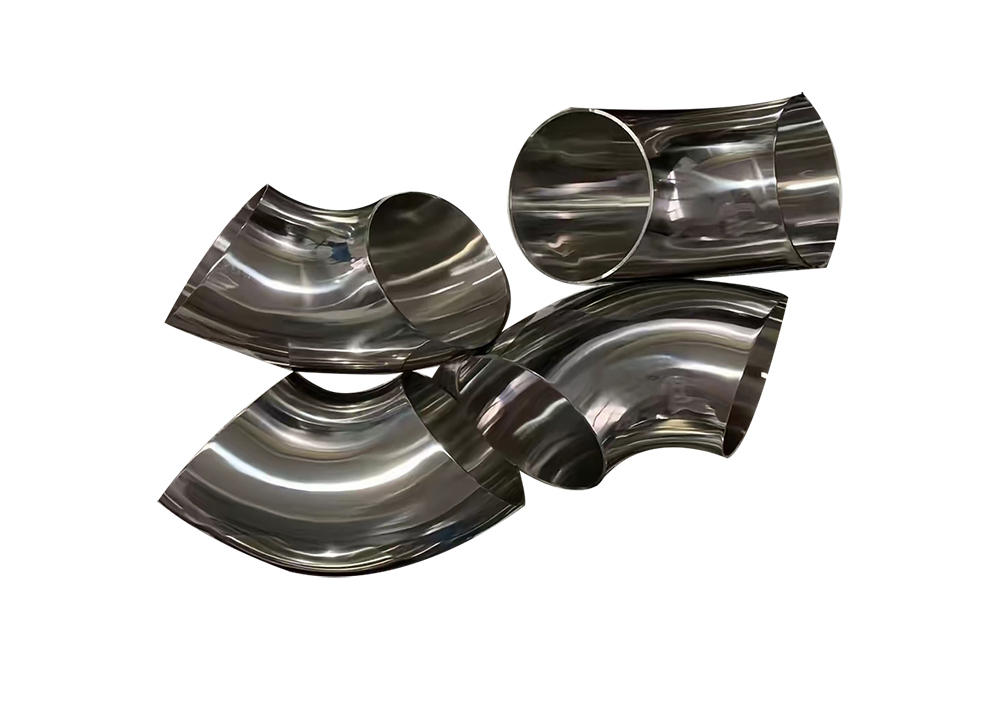

ASME B 16.9 Food Grade Sanitary Mirror Polish 90 Degree Titanium Weld Elbow

-

Highlight

Sanitary Mirror Polish Titanium Weld Elbow

,ASME B 16.9 Titanium Weld Elbow

,90 Degree Titanium Weld Elbow

-

MaterialTA1,TA2, Gr.1 BT1-00, Gr.1ELI, BT1-00CB,Gr.2 BT1-0 Etc

-

SizeDN15-DN 650(NPS1/2-NPS 26)

-

OEM/ODMAvailable

-

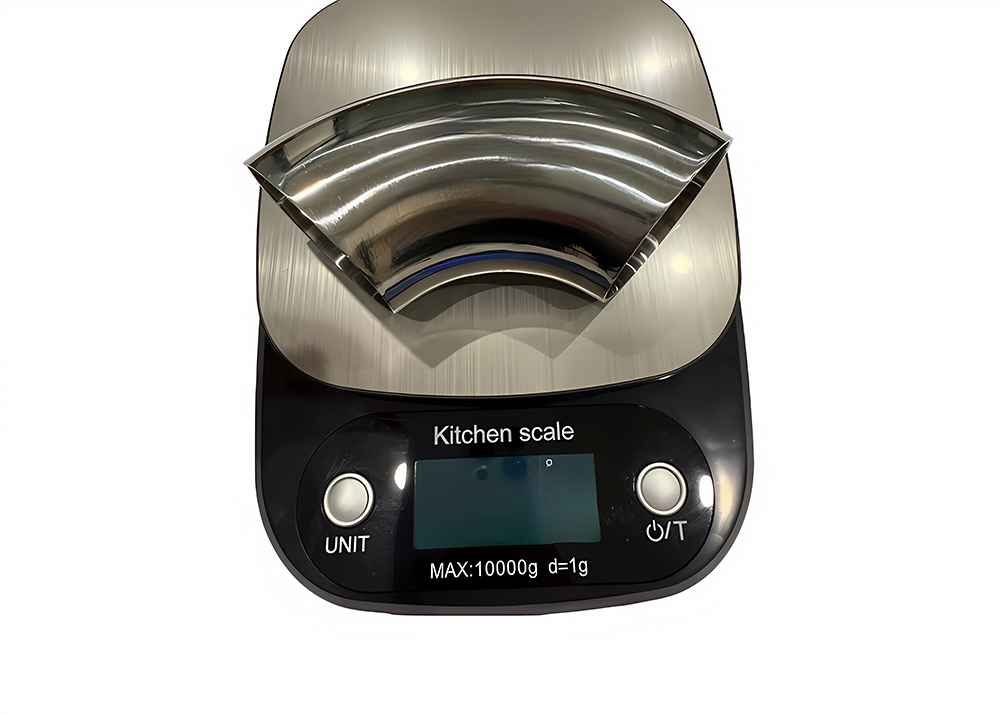

Titanium Surface FinishInner And Outer Surface Polishing

-

TechnicsWelding

-

TypeTitanium 90° Sanitary Elbow

-

Place of OriginShaanxi,China

-

Brand NameVOTECH

-

CertificationGB/T17684—2011,ASME B 16.9

-

Model NumberDN15-DN 650(NPS1/2-NPS 26)

-

Packaging DetailsExport Standard Wooden Case, or Can Be Customized

-

Delivery Time7-15 Days

-

Payment TermsMoneyGram,Western Union,T/T,D/P,D/A,L/C

-

Supply Ability100ton/Month

ASME B 16.9 Food Grade Sanitary Mirror Polish 90 Degree Titanium Weld Elbow

The Titanium 90° sanitary elbow is a specialized pipe fitting designed to change the direction of fluid flow in pipeline systems. Engineered for demanding sanitary-sensitive applications, it is widely used across industries including dairy, food and beverage, beer, biopharmaceutical, and daily chemicals.

This 90° sanitary titanium elbow ensures media purity through its exceptional corrosion resistance, high-temperature tolerance, superior strength, and lightweight properties. With a lifespan that significantly exceeds stainless steel, it is the ideal choice for high-sanitation process connections in food and pharmaceutical industries.

Available in specifications from DN15 to DN650, our Titanium 90° Sanitary Elbow fittings can also be custom-manufactured to meet specific customer requirements. All products are manufactured in strict compliance with international standards including ASME B16.9 and GB/T 17684-2011.

| Standard | GB/T17684--2011, ASME B 16.9 |

|---|---|

| Material | TA1, TA2, Gr.1 BT1-00, Gr.1ELI, BT1-00CB, Gr.2 BT1-0 etc |

| Size | DN15-DN 650 (NPS1/2-NPS 26) |

| OEM/ODM | Available |

| Surface Finish | Inner and Outer Surface Polishing |

| Technics | Welding |

| Type | Titanium 90° sanitary elbow |

| Packaging | Export standard wooden case, or can be customized |

| Application | Pharmaceutical Industry, Biotechnology & Biopharm, Food & Beverage Industry, Cosmetics Industry, Semiconductor & Electronics Industry, Chemical & Speciality Chemicals, Vehicle Exhaust System |

|

Nominal size |

|

Center to End |

Center to Center |

Back to Face |

|||||

|

90°Ebows |

45°Ebows |

180°return |

|||||||

|

DN |

NPS |

D |

LR |

SR |

LR |

LR |

SR |

LR |

SR |

|

15 |

1/2 |

21.3 |

38 |

- |

16 |

76 |

- |

48 |

- |

|

20 |

3/4 |

26.7 |

38 |

- |

19 |

76 |

- |

51 |

- |

|

25 |

1 |

33.4 |

38 |

25 |

22 |

75 |

51 |

56 |

41 |

|

32 |

1 1/4 |

42.2 |

48 |

32 |

25 |

95 |

64 |

70 |

52 |

|

40 |

1 1/2 |

48.3 |

57 |

38 |

29 |

114 |

76 |

83 |

62 |

|

50 |

2 |

60.3 |

76 |

51 |

35 |

152 |

102 |

106 |

81 |

|

65 |

2 1/2 |

73.0 |

95 |

64 |

44 |

191 |

127 |

132 |

100 |

|

80 |

3 |

88.9 |

114 |

76 |

51 |

229 |

152 |

159 |

121 |

|

90 |

3 1/2 |

101.6 |

133 |

89 |

57 |

267 |

178 |

184 |

140 |

|

100 |

4 |

114.3 |

152 |

102 |

64 |

305 |

203 |

210 |

159 |

|

125 |

5 |

141.3 |

190 |

127 |

79 |

381 |

254 |

262 |

197 |

|

150 |

6 |

168.3 |

229 |

152 |

95 |

457 |

305 |

313 |

237 |

|

200 |

8 |

219.1 |

305 |

203 |

127 |

610 |

406 |

414 |

313 |

|

250 |

10 |

273 |

381 |

254 |

159 |

762 |

508 |

518 |

391 |

|

300 |

12 |

323.8 |

457 |

305 |

190 |

914 |

609 |

619 |

467 |

|

350 |

14 |

355.6 |

533 |

356 |

222 |

1067 |

711 |

711 |

533 |

|

400 |

16 |

406.4 |

610 |

406 |

254 |

1219 |

813 |

813 |

610 |

|

450 |

18 |

457.0 |

686 |

457 |

286 |

1372 |

914 |

914 |

686 |

|

500 |

20 |

508.0 |

762 |

508 |

318 |

1524 |

1016 |

1016 |

762 |

|

550 |

22 |

559.0 |

838 |

559 |

343 |

1676 |

1118 |

1118 |

838 |

Titanium pipe fittings have extremely strong resistance to corrosive media such as seawater and chloride ions. Their corrosion resistance far exceeds that of stainless steel and carbon steel, making them especially suitable for harsh environments such as marine and chemical industries.

No additional measures are needed. Titanium 90° sanitary elbows can be used for extended periods without coating or cathodic protection, eliminating rust risk and significantly reducing maintenance requirements.

Titanium offers strength comparable to steel but with only 60% of steel's density. This enables significant weight reduction in equipment for aerospace and shipbuilding applications while maintaining high load-bearing capacity.

Titanium alloys (such as TA2 and TA9) maintain stable mechanical properties at 300-500℃, with some materials capable of withstanding even higher temperatures for short durations.

While the initial purchase cost is higher, titanium fittings offer an extremely long service life with minimal maintenance, resulting in superior long-term cost-effectiveness.

Yes. Titanium's non-toxic, biocompatible nature and high material purity make it ideal for meeting strict hygiene requirements in pharmaceuticals and food processing.

- Strict Quality: Rigorous quality control measures complying with ASME, JIS, DIN, GB, GOST standards ensure all titanium products meet industry and customer requirements.

- Modern Production Facilities: Advanced factory with multiple titanium metal production lines enables handling of bulk orders and customized projects.

- Logistics and Packaging: Every order is carefully packed in wood cabins or trays to prevent transit damage, offering maximum protection.

- Experienced Team: Years of professional knowledge in titanium metal manufacturing ensures high-quality products for diverse industries.

- Comprehensive Service: Customized solutions, fast lead times, and dedicated support throughout the purchasing process.

- Customer-Centric Services: Flexible payment options, comprehensive technical support, and dedicated customer service for a seamless experience.