1-6in Petroleum Oil Pipe Internal Thread Taper Lead Gauge Measuring Instrument

-

Highlight

1-6in Thread Taper Lead Gauge

,Petroleum Thread Taper Lead Gauge

,Oil Pipe Thread Taper Lead Gauge

-

WarrantyOne Year

-

Measurement ObjectInter Thread Taper

-

Range1-6"(25.4mm-152.4mm)

-

Graduation0.001"

-

Range Ability25.4-152.4mm

-

ApplicationOil Pipe Thread Measurement

-

PackageAluminum Case

-

Place of OriginShaanxi, China

-

Brand NameKM

-

CertificationISO DIN GB RoHS

-

Model NumberKM-ITTG-1

-

Packaging DetailsAluminum Case 40*31*5cm/Piece 4.00kg/Piece

-

Delivery TimeWithin 15days

-

Payment TermsT/T,L/C,D/P,D/A,Western Union,PayPal,MoneyGram

-

Supply Ability50000pieces/Month

1-6in Petroleum Oil Pipe Internal Thread Taper Lead Gauge Measuring Instrument

1-6in Petroleum Oil Pipe Internal Thread Taper Lead Gauge Measuring Instrument

Quick Detail:

1. used to measure the taper of external thread for the API Spec 5B standard threads.

2. Select the proper contact point for your particular measurement requirement.

Description:

Our oil pipe thread instruments are the special precision measuring instruments in the oil industry, mainly used to measure

parameters of thread taper, thread pitch and thread height for oil pipe, such as casing pipe, oil pipe, pipe line and drill pipe.

Our oil pipe thread instruments include oil pipe outer/inner thread taper instrument, outer/inner thread pitch instrument,

outer/inner thread height instrument, etc.

This is internal thread taper measuring instrument, used for measuring internal thread taper, measuring range 1-6in(25.4-152.4mm),

supply two types measuring head, one is 1.829 measuring head for measuring 8 thread and 1.448 measuring head

for measuring 10 thread. When you order, please let us know the thread type needs to be measured, we will provide the best solution.

Our oil pipe thread instruments are manufactured and calibrated critically to the exact standards&ISO9001 management standards,

they meet national standard# JJF1063-2000 and JJG42-96 as well as API STD 5B standard too.

Specification:

|

Order No. |

Range |

Range of Indicator |

Graduation |

|

KM-ITTG-1 |

1-6″ (25.4-152.4mm) |

0-1″ |

0.001″ |

|

KM-ITTG-2 |

5 1/2-16″(139.7-406-4mm) |

0-0.5″ |

0.001″ |

|

KM-ITTG-3 |

1-5″(25.4-152.4mm) |

0-0.5″ |

0.001″ |

Precautions:

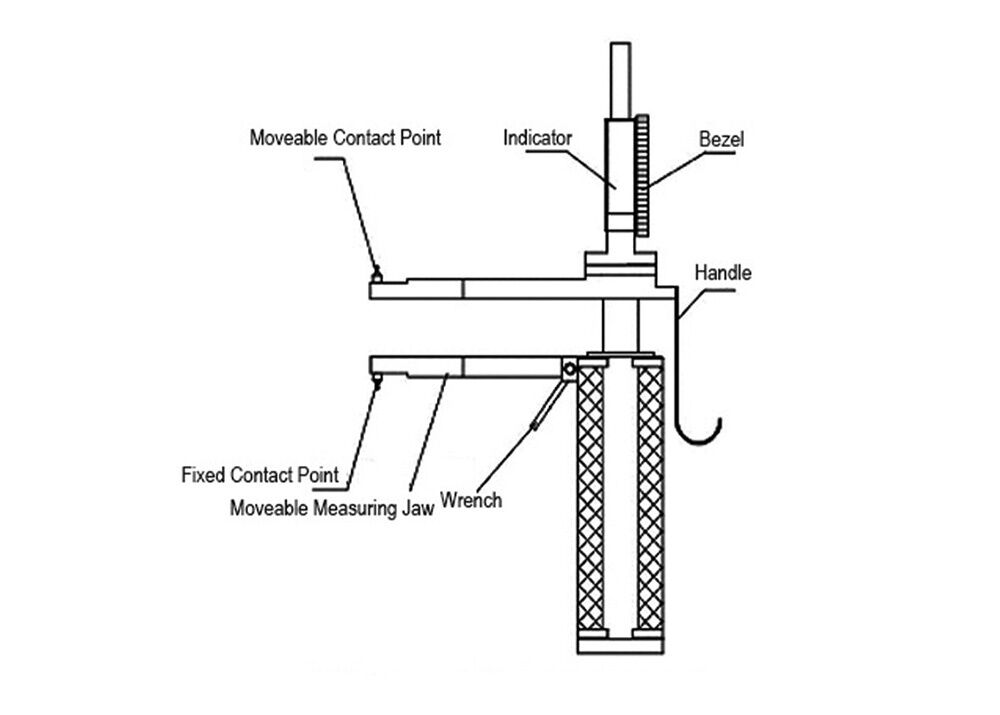

1. Make a measurement mark on the inner thread and determine the measurement position.

2. Refer to the appendix "Probe Usage List", install on the measuring head that is suitable for the thread to be measured.

3. Rotate the wrench to loosen the moveable measuring jaw, adjust the moveable measuring jaw to the diameter position

of the internal thread, press down the handle, place the fixed measuring head in the alveolar of the first (or last) tooth

of the complete thread, place the moveable measuring head in the alveolar on the opposite side of the same tooth diameter,

and the measuring rod of the indicator has a certain amount of pressure.

4. The fixed measuring head is kept in a fixed position, the moveable measuring head is rotated in a small arc in the alveolar,

rotate the bezel of the indicator to make the zero position coincide with the maximum indicating reading, and lock the bezel.

5. Measure along the marked measuring position in turn, and record the reading on the table, the reading value is the taper value

within the interval of the internal thread. Compare this taper value with the standard taper value to determine whether the thread

taper is qualified.

Applications:

Oil pipe thread instruments are widely used in the oil industry for measuring geometric accuracy of pipe threads for oil pipes,

such as casing pipe, oil pipe, pipe line and drill pipe.

FAQ:

1) Who are we?

Deko Corporation mainly dedicate to the development, manufacture and marketing of KM brand precision measuring tools

in China mainland.

2) What products do we carry?

Dial indicators, micrometers, calipers, bore gauges, height gauges, dial thickness gauges, depth gauges, bevel protractors,

gauge, blocks, level, etc.

3) What are the terms of trade?

We support FOB, CFR, CIF, EXW.

4) What are the forms of payment?

We accept T/T, L/C, D/A, D/P, PayPal, Western Union.

5) Do we accept customization?

Yes, OEM is available.

6) How about after-sales service?

One year warranty for all kinds of products.

If you find any defective accessories when receive goods, we will ship your news parts or new product to replace.

As an experienced manufacturer, we have very strict calibration and inspection team, you can rest assured of our product quality.