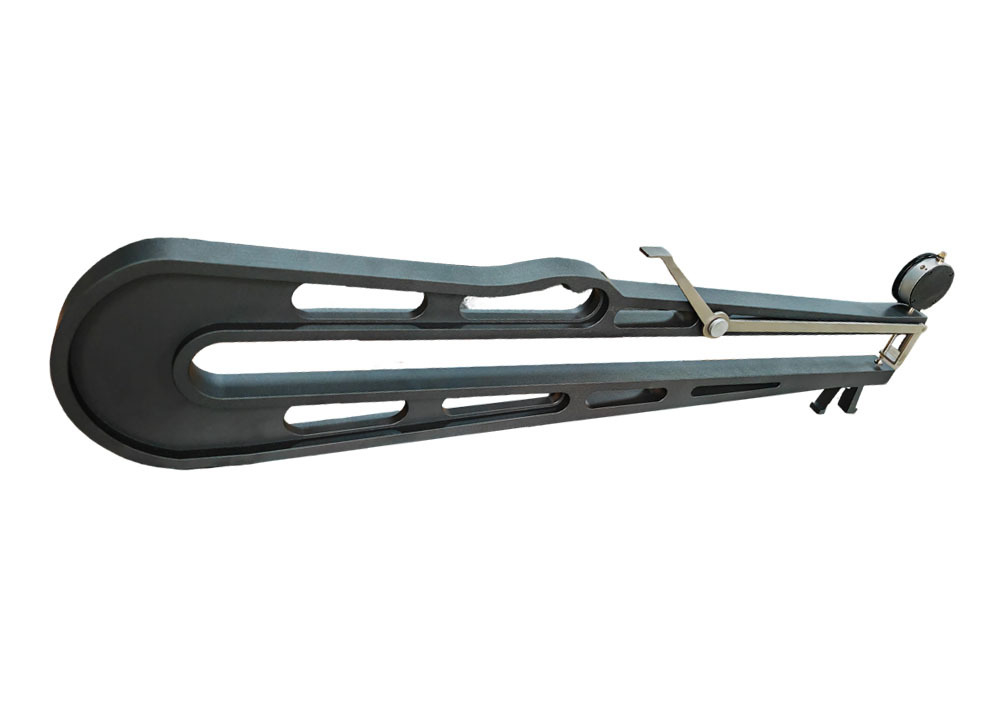

Large Depth 0-30mm Dial Thickness Gauge High Precision Mechanical Thickness Gauge

-

Highlight

0-30mm dial thickness gauge

,high precision mechanical thickness gauge

,large depth dial thickness gauge

-

WarrantyOne Year

-

TypeDial Bore Gauge

-

MeasurementMetric

-

MaterialStainless Steel

-

ApplicationInternal Measurement

-

Range0-30mm

-

Graduation0.01mm

-

Measuring Depth700mm

-

PackageWooden Box

-

Measuring Force1.5 - 2.5 N

-

Measuring FaceSpherical Measuring Face

-

CustomizedAcceptable

-

Place of OriginShaanxi, China

-

Brand NameKM

-

CertificationISO DIN GB RoHS

-

Model NumberKM-422-090

-

Packaging DetailsWooden Box 98*28*8cm/Piece 6.50kg/Piece

-

Delivery TimeWithin 15days

-

Payment TermsT/T,L/C,D/P,D/A,Western Union,PayPal,MoneyGram

-

Supply Ability50000pieces/Month

Large Depth 0-30mm Dial Thickness Gauge High Precision Mechanical Thickness Gauge

Large Depth 0-30mm Dial Thickness Gauge High Precision Mechanical Thickness Gauge

Product Overview

Dial thickness gauge mainly used to measure the thickness of various materials such as metal sheets, plastics, rubber, paper, etc.

It features precision measurement and easy to use, the dial indicator is wear resistant and transparent, the scale is clear and easy to read.

Thickness gauges supply measuring range from 0-10mm up to 0-50mm, the measuring depth are available from 26mm up to 500mm

to meet different measurement application, we also can customize measuring depth based on requirement.

Thickness gage available with 26mm,30mm,60mm,120mm, 200mm and 300mm, we also can customize wider measuring depth

up to 800mm to meet special measurement requirement.

Key Features

- Measures thickness of various materials including metal sheets, plastics, rubber, and paper.

- Quick and efficient measurement with convenient grip handle.

- Lifting lever for dial indicator.

- Multiple measuring face options (steel or ceramic) for diverse applications.

- Customizable measuring depth available.

- Includes protective fitted case.

- Wear-resistant, transparent dial indicator with clear, easy-to-read scale.

Technical Specifications

| Order No. | Measuring Range | Graduation | Measuring Depth |

|---|---|---|---|

| KM-422-090 | 0-30mm | 0.01mm | 700mm |

Available Measuring Depths

Standard options include 26mm, 30mm, 60mm, 120mm, 200mm, and 300mm. Custom depths up to 800mm available for special measurement requirements.

Usage Precautions

- Handle with care to prevent impact or falls that may affect accuracy.

- Keep clean and dry to maintain optimal performance.

- Avoid exposure to liquids and electrical currents.

- Do not engrave or mark on the gauge surface.

Industrial Applications

- Iron and steel industry: Measuring thickness of metal sheets for ships, bridges, and oil tanks.

- Chemical industry: Measuring wall thickness of containers and pipelines.

- Manufacturing: Measuring plastic products, paper, leather, rubber, fabric, and glass.

- Aerospace: Measuring aircraft and engine components.

- Automotive: Measuring body panels, brake discs, and other parts.

Frequently Asked Questions

Who are we?

Deko Corporation specializes in the development, manufacture, and marketing of KM brand precision measuring tools in China mainland.

What products do we carry?

Our product line includes dial indicators, micrometers, calipers, bore gauges, height gauges, dial thickness gauges, depth gauges,

bevel protractors, gauge blocks, and levels.

What are the terms of trade?

We support FOB, CFR, CIF, and EXW trade terms.

What are the forms of payment?

We accept T/T, L/C, D/A, D/P, PayPal, and Western Union.

Do we accept customization?

Yes, OEM services are available.

How about after-sales service?

All products come with a one-year warranty. Defective parts will be replaced promptly. Our strict calibration and inspection processes

ensure product quality and reliability.